Manual Spiral Staircase Lathe

November 4, 2024Manual spiral staircase lathes are specialized machines used to create the intricate, curved components of spiral staircases. These powerful tools offer unparalleled precision and control, allowing skilled craftsmen to craft stunning and durable staircases. Understanding the intricacies of these machines is essential for anyone involved in the design, fabrication, or installation of spiral staircases.

Understanding the Manual Spiral Staircase Lathe

A manual spiral staircase lathe, often referred to as a stair router or spindle lathe, is a woodworking machine designed specifically for shaping the various elements of a spiral staircase, including the handrails, balusters, and newel posts. Unlike conventional lathes, these machines allow for the creation of complex curves and spirals, making them ideal for this specific application. The operator manually controls the cutting tools, requiring a high level of skill and expertise. This hands-on approach allows for a greater degree of customization and intricate detail work.

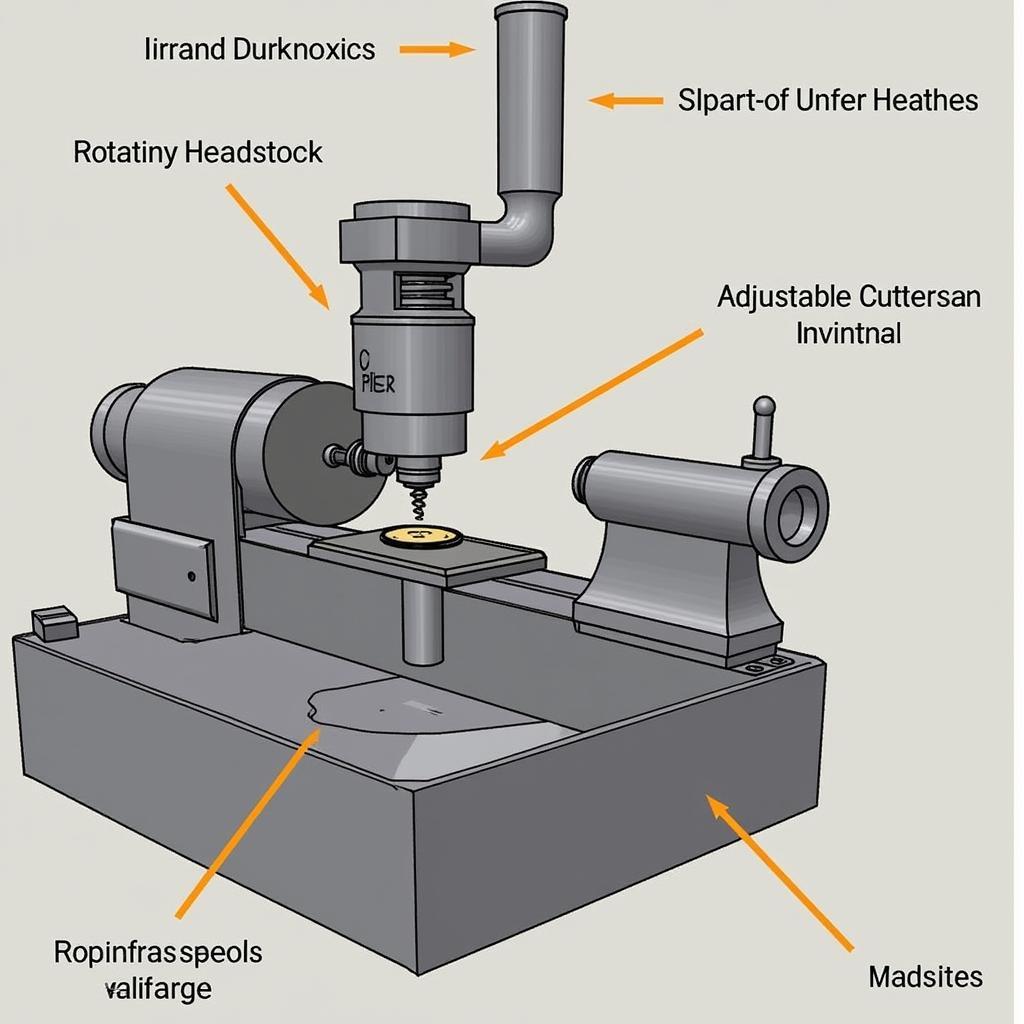

Key Features of a Manual Spiral Staircase Lathe

Several key features distinguish manual spiral staircase lathes from other woodworking machinery:

- Rotating Headstock: This holds and rotates the workpiece, allowing for even and controlled cutting.

- Adjustable Cutter Head: The cutter head can be adjusted to create various profiles and depths of cut, enabling the creation of complex shapes.

- Manual Feed System: The operator manually feeds the workpiece into the cutter, providing precise control over the shaping process.

- Variable Speed Control: Adjusting the speed of the rotating headstock is crucial for different wood types and cutting operations.

- Sturdy Construction: A robust frame ensures stability and minimizes vibrations during operation.

Components of a Manual Spiral Staircase Lathe

Components of a Manual Spiral Staircase Lathe

Benefits of Using a Manual Spiral Staircase Lathe

Manual spiral staircase lathes offer several advantages:

- Precision and Accuracy: Manual control allows for intricate detailing and precise shaping of staircase components.

- Versatility: These machines can accommodate various wood types and sizes, enabling the creation of diverse staircase designs.

- Durability: The precise and controlled cutting process contributes to the creation of strong and durable staircase components.

- Customization: Manual operation allows for a high level of customization, enabling craftsmen to create unique and bespoke staircases.

How to Operate a Manual Spiral Staircase Lathe Safely

Operating a manual spiral staircase lathe requires careful attention to safety:

- Wear appropriate safety gear: This includes eye protection, hearing protection, and a dust mask.

- Secure the workpiece: Ensure the workpiece is firmly secured in the rotating headstock to prevent accidents.

- Use sharp cutting tools: Dull tools can increase the risk of kickback and other hazards.

- Maintain a safe distance: Keep hands and other body parts away from the rotating cutter head.

- Follow manufacturer instructions: Always consult the manufacturer’s instructions for specific safety guidelines.

“A manual spiral staircase lathe allows for unparalleled artistry in staircase construction. The ability to shape each component by hand is essential for achieving truly bespoke designs,” says renowned staircase craftsman, Arthur Blackwood.

Safety Gear for Manual Spiral Staircase Lathe Operation

Safety Gear for Manual Spiral Staircase Lathe Operation

Conclusion

Manual spiral staircase lathes are essential tools for crafting elegant and durable spiral staircases. These machines offer precise control, versatility, and the potential for intricate detailing. By understanding the key features, benefits, and safety procedures, craftsmen can unlock the full potential of these powerful tools and create truly stunning staircases. Remember, investing in a high-quality manual spiral staircase lathe is an investment in craftsmanship and the creation of lasting architectural elements.

FAQ

- What types of wood can be used with a manual spiral staircase lathe?

- What is the average cost of a manual spiral staircase lathe?

- What maintenance is required for a manual spiral staircase lathe?

- What are the different types of cutting tools used with a manual spiral staircase lathe?

- Where can I find training on how to operate a manual spiral staircase lathe?

- What are the common problems encountered when using a manual spiral staircase lathe?

- What safety precautions should be taken when operating a manual spiral staircase lathe?

“Regular maintenance is crucial for ensuring the longevity and optimal performance of your manual spiral staircase lathe,” advises Eleanor Vance, a seasoned woodworking machinery technician.

For further information, you might find these articles helpful: “Choosing the Right Wood for Your Spiral Staircase” and “A Beginner’s Guide to Spiral Staircase Design.”

Need support? Contact us at Phone Number: 0396443476, Email: [email protected] Or visit us at: 23 Tháng 3, Đắk Nia, Gia Nghĩa, Đắk Nông, Việt Nam. We have a 24/7 customer service team.